I always have been curious about how exoskeletons work but searching for learning materials comes with a big prerequisite of knowledge. However upon discovering EduExo, it gave me a good place to start.

I started with EduExo Maker as that was open source. They have provided all code and STL files and a handbook.

But of course I decided to branch off a bit…

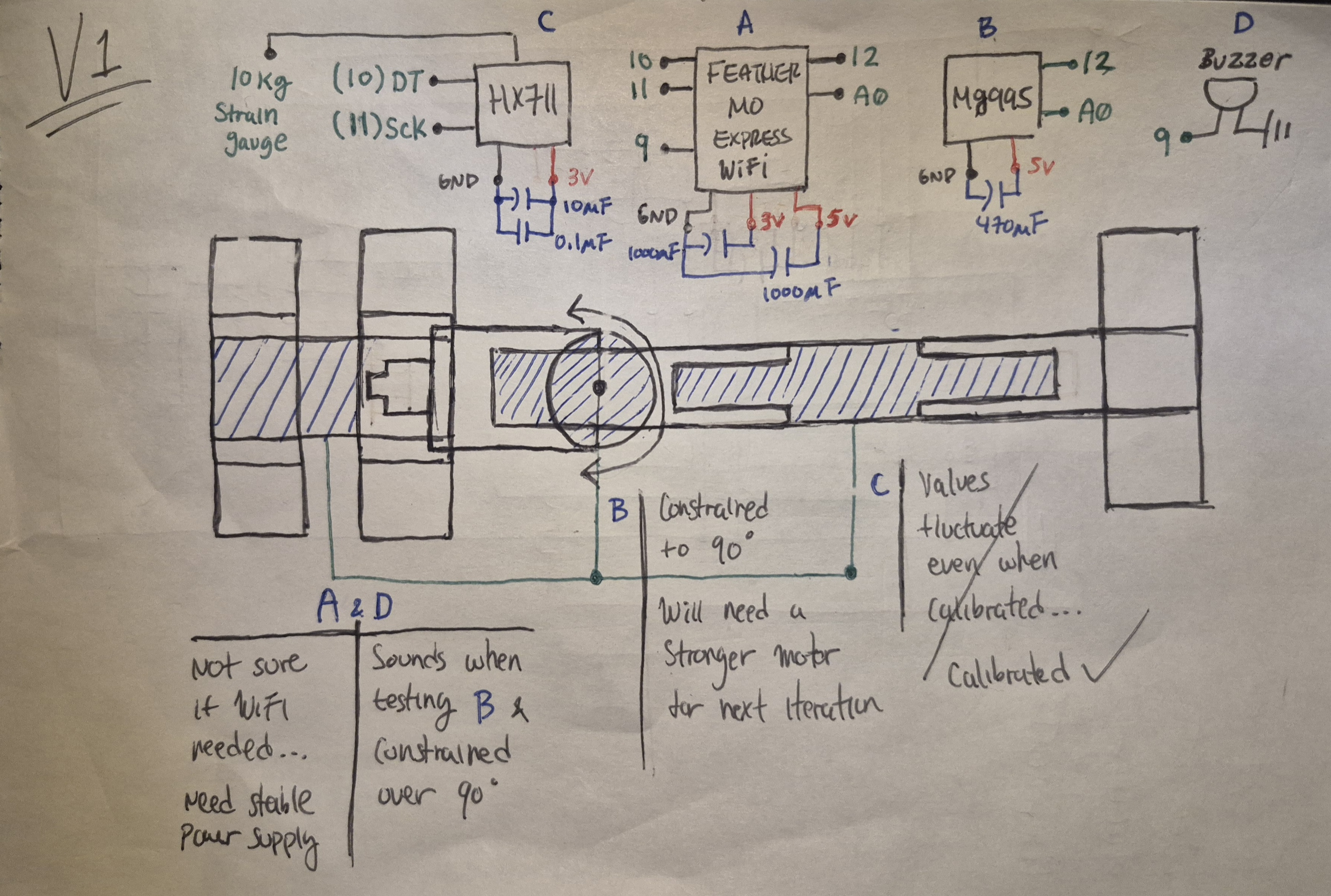

Hardware

- EduExo

- Adafruit Feather M0 WiFi - ATSAMD21 + ATWINC1500

- MG995R Servo

- 10 kg strain gauge load cell

- HX711 load cell amplifier

A strain gauge measures mechanical force and converts that into an electrical signal. There are different kinds of load cells. The HX711 helps interface the load cell easily and provides accurate measurements.

The handbook says to get an analog feedback servo. They have feedback on what position they are in. I did not have one on hand (you think I would) so I instead used the MG995R and modified that to have feedback.

Schematic & Diagram

It wouldn’t be a good project without issues!

I experienced fluctuating values when measuring force even when I calibrated it. Luckily I found an example from SparkFun that FINALLY calibrated my load cell.

There was also this weird issue where the servo locked up from the 5V power supply coming from the M0. Eventually it worked out and it was the way I setup the servo position…

To avoid any flucations to power and the modules, I added a few capacitors to smooth them out.

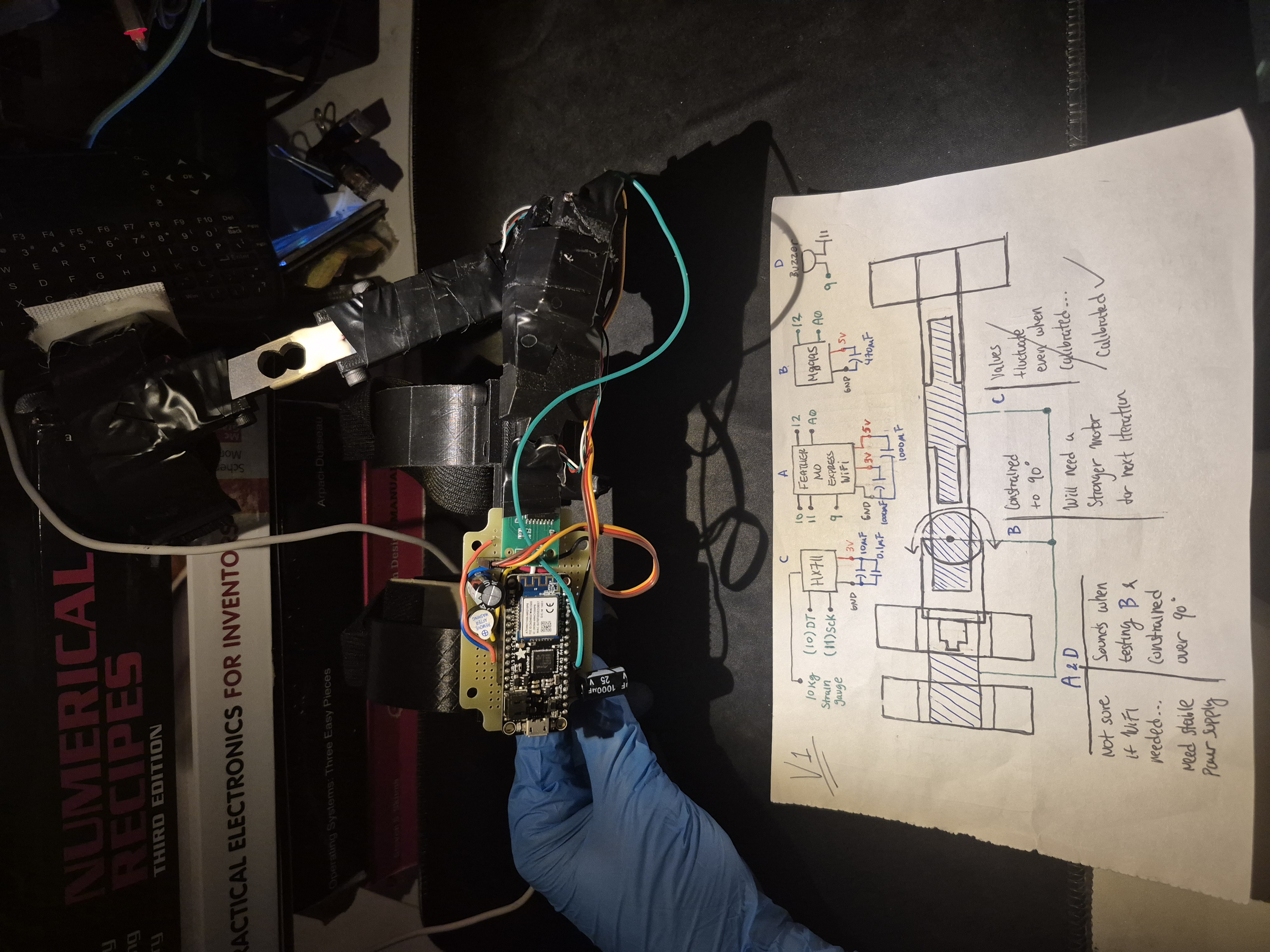

I wanted to continue on with this version but the PLA proved too fragile and has damaged several parts of the exo arm to which I had to super glue and electrical tape to hold it up. The next version will have improvements.

Software

As you can see the PID header I wrote was a follow up but as mentioned I had put it on hold.

#include <PID.h>

#include <SPI.h>

#include <HX711.h>

#include <Servo.h>

// piezo buzzer

#define BUZZER_PIN 9

// servo configurations

#define FEEDBACK_SERVO_PIN A0

#define PWM_SERVO_PIN 12

#define MIN_DEGREES 0

#define MAX_DEGREES 180

#define CONSTRAIN_DEGRESS 110

// HX711 configurations

#define DT 10

#define SCK 11

#define READING -44000.00 // based on calibration result | 479.0, -60.41

#define TEST_FLAG 1 // 0 to calibrate || 1 to ignore

#define KNOWN_WEIGHT 1.034 // in grams (change accordingly) | 27.0, 1.034 kg

HX711 hx711;

float hx711Calibration;

// servo

Servo servo;

int servoPos;

int feedbackPos;

int minDegrees;

int maxDegrees;

int minFeedback;

int maxFeedback;

int tolerance;

// PID controller

struct PID pid;

float integ;

long interval;

long prevTime;

long currTime;

float ut;

void hx711Calibrate()

{

if(TEST_FLAG == 0)

{

hx711.set_scale();

Serial.println("Tare... remove any weights from the scale.");

delay(5000);

hx711.tare();

Serial.println("Tare done...");

Serial.print("Place a known weight on the scale...");

delay(5000);

long reading = hx711.get_units();

Serial.println("Result:\n");

Serial.print(reading);

hx711Calibration = reading/KNOWN_WEIGHT;

Serial.println("Calibrated value:\n");

Serial.print(hx711Calibration);

}

else

{

hx711Calibration = READING / KNOWN_WEIGHT;

Serial.println("HX711 ALREADY CALIBRATED....");

Serial.println("Result:\n");

Serial.print(hx711Calibration);

}

}

void servoTest()

{

// beep test before

// proceeding to test

for(int i=0; i<4; i++)

{

tone(BUZZER_PIN, 1000,50);

delay(200);

noTone(BUZZER_PIN);

}

servo.write(100);

delay(1000);

servo.write(0);

delay(1000);

servo.write(100);

delay(1000);

}

void setup() {

Serial.begin(115200); // 115200 9600

pinMode(BUZZER_PIN, OUTPUT);

servo.write(100);

servo.attach(PWM_SERVO_PIN);

servoTest();

servo.detach();

hx711.begin(DT,SCK);

hx711Calibrate();

hx711.tare();

}

void loop()

{

hx711.set_scale(hx711Calibration);

if(hx711.is_ready())

{

feedbackPos = constrain(map(analogRead(FEEDBACK_SERVO_PIN),0,1023,MIN_DEGREES,MAX_DEGREES),MIN_DEGREES,MAX_DEGREES);

Serial.print(">Servo Feedback:");

Serial.println(feedbackPos);

Serial.print(">HX711 Units:");

Serial.println(hx711.get_units(),1);

// Serial.print(">HX711 Average:");

// Serial.println(hx711.read_average(1),1);

// safety check (0 - 90 deg arm bend)

// resets back resting position (96 deg)

if(feedbackPos > CONSTRAIN_DEGRESS)

{

tone(BUZZER_PIN, 1000);

if(!servo.attached())

{

servo.attach(PWM_SERVO_PIN);

servo.write(100);

}

else

{

servo.write(100);

}

delay(350);

noTone(BUZZER_PIN);

servo.detach();

}

}

}

Demo

A simple sweep test

(don’t mind the books and the electrical tape…)

(don’t mind the books and the electrical tape…)